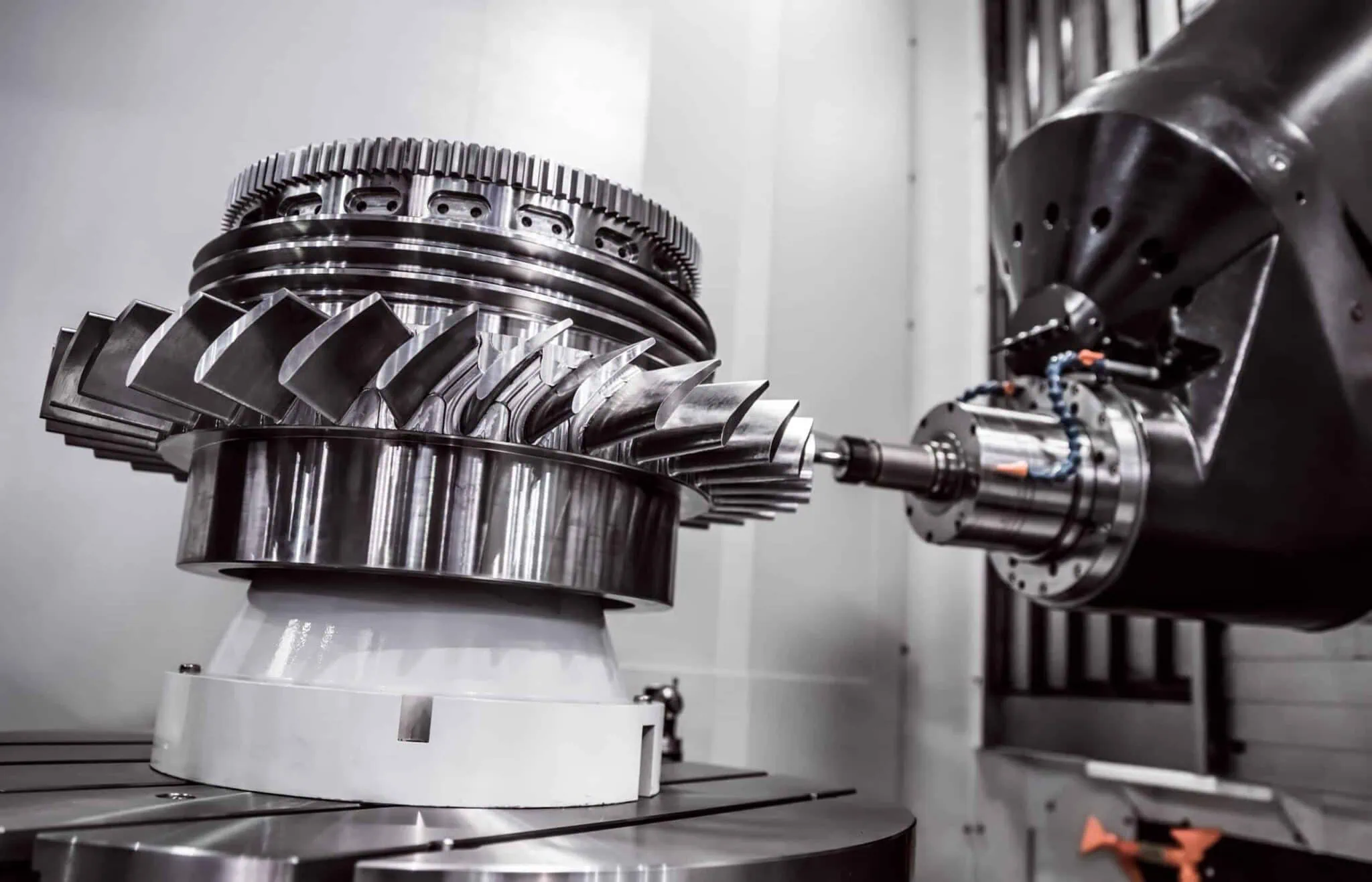

5 AXIS SERVICES

Our high-precision 5-axis CNC machining center from DMG enables the processing of complex freeform surfaces up to 500 mm in diameter in a single setup. This machine delivers top performance, especially for complex geometries in the aerospace, defense, mold making, and medical technology industries.

- Maximum machining diameter: 500 mm

- Simultaneous for inclined surfaces and complex multi-sided machining

- High repeatability and positioning accuracy

- CAM-supported production (compatible with Siemens/Heidenhain)

- Wide range of materials: aluminum, steel, stainless steel, plastic, titanium, and more

- Prototype production

- Mold making

- Precision mechanics

- Multi-sided machining

- Aerospace components

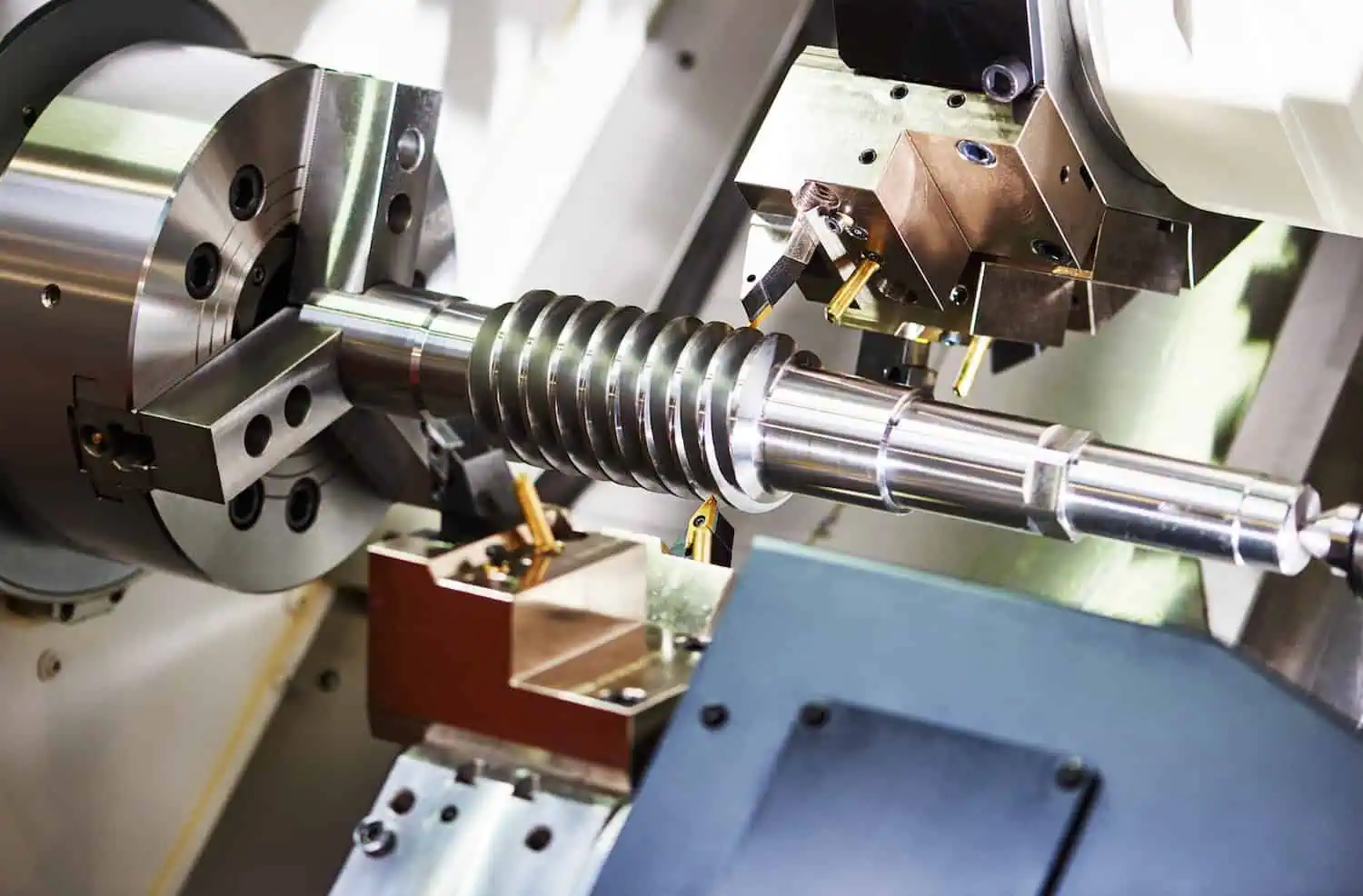

CNC TURNING SERVICES

Our C and Y axis DMG CNC lathes allow for precise machining of large and complex workpieces with diameters up to 700 mm and lengths up to 1200 mm. Thanks to their multi-axis machining capabilities, both turning and milling operations can be efficiently performed in a single setup.

- Maximum machining diameter: 700 mm

- Maximum workpiece length: 1200 mm

- Axes: C axis (contour precision milling), Y axis (off-center machining)

- Combined turning and milling in a single setup

- High precision and excellent surface quality

- Processing of bar, cast, and forged parts is possible

- CAM-supported production

- Heavy-duty engineering components

- Flanges

- Mills

- Fasteners

- Cast parts

- Complex large components

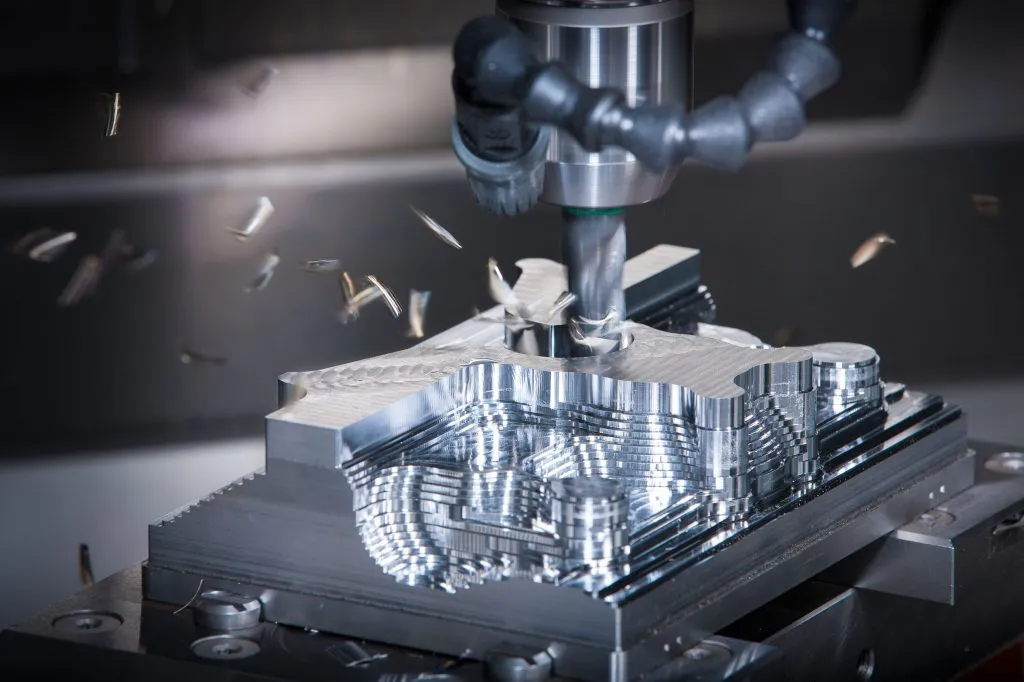

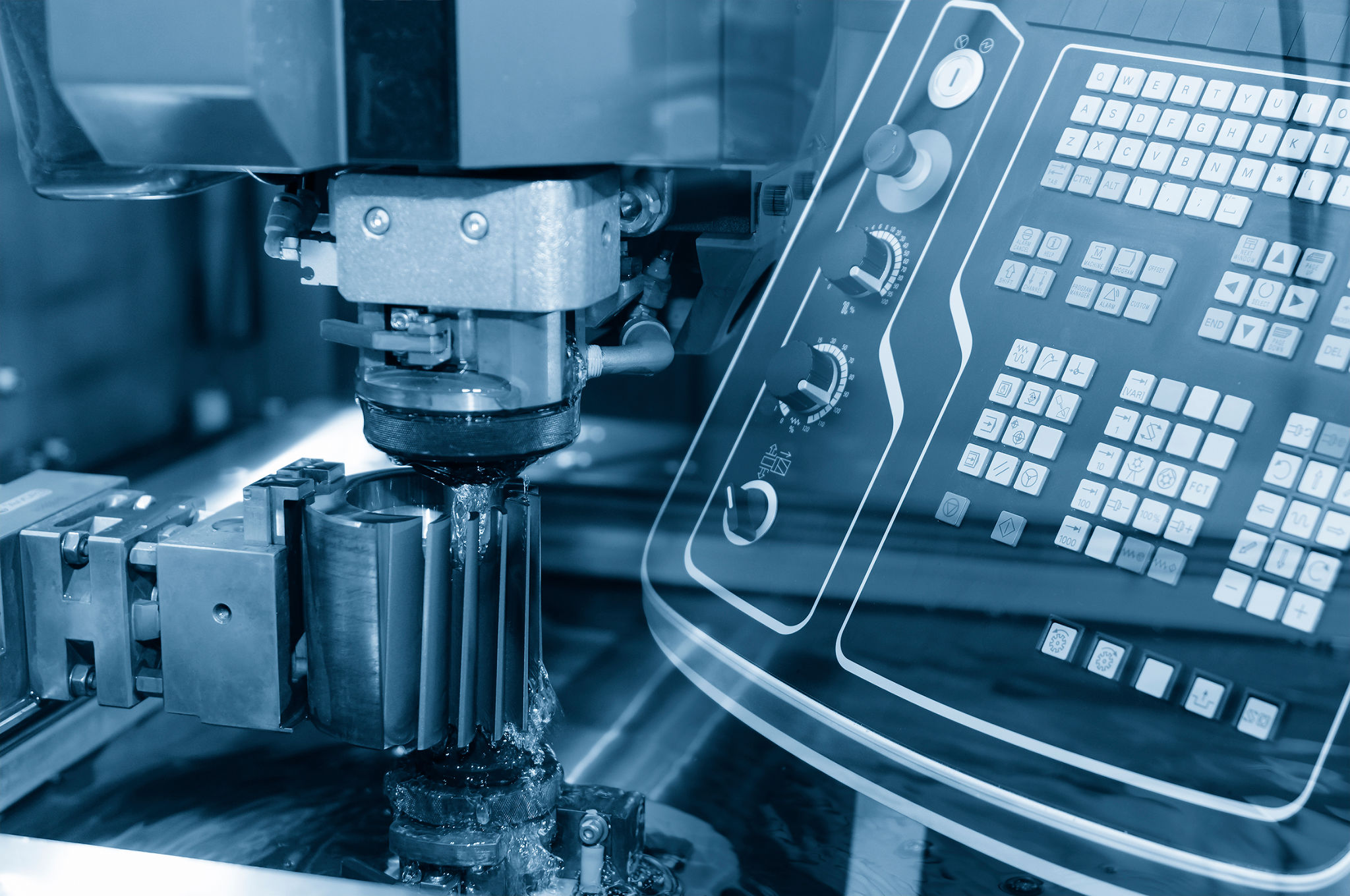

CNC MILLING SERVICES

Our DMG 3-axis and 4-axis vertical machining centers offer a generous machining area of 1500 x 700 x 700 mm, ideal for the precise machining of complex parts with high efficiency. These machines are suitable for both mass production and prototype manufacturing, providing versatile solutions with their 4-axis machining capabilities.

- Machining area: 1500 mm x 700 mm x 700 mm

- Axes: 3 axes (X, Y, Z) and 4 axes (additional rotary motion for advanced machining)

- High machining speed and precision

- Advanced cooling systems and vibration damping technology

- Wide range of materials: aluminum, steel, stainless steel, plastic, titanium, and more

- CAM-supported production

- Multi-sided machining in a single setup

- Precision mechanics

- Prototype production

- Mold making

- Automotive parts

- Aerospace and defense

- Electronics and medical technology

WIRE EDM SERVICES

We offer superior accuracy and surface quality with our wire EDM machines for the production of complex and finely toleranced parts. We provide reliable solutions, especially in mold making, prototyping, and precision engineering applications.

- Maximum workpiece size: 600 x 400 x 300 mm

- Cutting with ±2 micron precision

- Detailed machining with very fine wire diameters

- Automatic wire changing and high efficiency

- Compatible with steel, aluminum, copper, hardened steel, and special alloys

- CAM-supported programming

- Smooth cutting in heat-treated and hard materials

- Mold and die part production

- Precision mechanics and prototype parts

- Electrical-electronic and medical components

- Automotive and defense industry special parts

- Thin-walled and complex geometrical workpieces

CNC LASER SERVICES

With a power output of 12 kW and a generous cutting area of 6096 mm x 2540 mm, our CNC laser cutting machines offer extremely precise and efficient cutting operations. They ensure the precise cutting of metal and alloy materials, especially for thick sheets and complex components.

- Laser power: 12 kW

- Cutting area: 6096 mm x 2540 mm

- Processable materials:

- Black sheet (S235): up to 30 mm

- Stainless steel (304): up to 25 mm

- Aluminum (5083): up to 25 mm

- Copper (CU): up to 20 mm

- Brass (CUZN39 PB3): up to 20 mm

- High cutting speed and efficiency: Fast cutting operations with low tolerances and high quality

- CNC control system: Advanced software support for simple and precise cutting operations

- High precision: Precise cutting of fine details and complex geometries

- Metal processing

- Automotive and aerospace industries

- Electronic components and mechanical engineering

- Sign making and prototype production

- Construction, industry, and many other applications of laser cutting technology

WELDING AND ASSEMBLY SERVICES

With our expert team and modern equipment, we offer high quality and durability in the welding, assembly, and joining of metal parts. You can safely deliver your projects with solutions compliant with industrial standards.

- MIG, TIG, and spot welding technologies

- Welding applications in different thicknesses and materials

- Automatic and manual welding options

- Assembly line and custom fixture support

- Post-weld surface finishing and inspection

- Testing and quality control of welded and assembled parts

- Machine and equipment bodies

- Steel construction and skeleton systems

- Automotive and defense industry parts

- Industrial assembly and sub-assembly groups

- Special projects and prototype assemblies

QUALITY CONTROL AND MEASUREMENT SERVICES

For high-precision measurement requirements, we use our ZEISS 3D coordinate measuring machine (CMM), which can measure workpieces up to 300 mm with micron precision. It provides reliable and repeatable results in quality control and reverse engineering applications.

- Measurement volume: up to 300 mm (X/Y/Z axes)

- Brand/model: ZEISS CMM

- Measurement accuracy: in the micron range

- Touch probe system: compatible with pen and scanning sensors

- CAD-supported evaluation and reporting (e.g., with ZEISS CALYPSO)

- Component verification

- First article inspection

- Mold and tool measurement

- Reverse engineering

- Fast and precise measurement results

- Comparison of complex geometries with CAD models

- Measurements according to ISO standards and customer specifications

SURFACE TREATMENT SERVICES

We offer various surface treatment solutions to enhance the durability, corrosion resistance, and aesthetic appearance of your parts. With our modern equipment and expert staff, we safely perform high-quality surface treatments in accordance with high standards.

- Anodizing, electrostatic powder coating, galvanizing, and chemical coating

- Sandblasting, polishing, and surface finishing processes

- Solutions suitable for different metals and alloys

- Surface roughness and color options

- Environmentally friendly and RoHS compliant processes

- Quality control and measurement reports

- Machine and equipment parts

- Automotive and aerospace components

- Electronics and medical devices

- Industrial and architectural applications

- Prototype and mass production parts

DESIGN AND ENGINEERING

With our experienced engineering team, we offer innovative and production-oriented design solutions tailored to customer demands. We quickly and efficiently turn your ideas into production with CAD/CAM-based project planning.

- 3D CAD modeling and technical drawing preparation

- CAM programming and production integration

- Reverse engineering and revision support

- Material and production method optimization

- Design suitable for prototype and mass production

- Compliance with international standards

- Machine and equipment design

- Automotive, aerospace, and defense projects

- Medical and electronic product development

- Mold and fixture design

- Prototype and special production projects

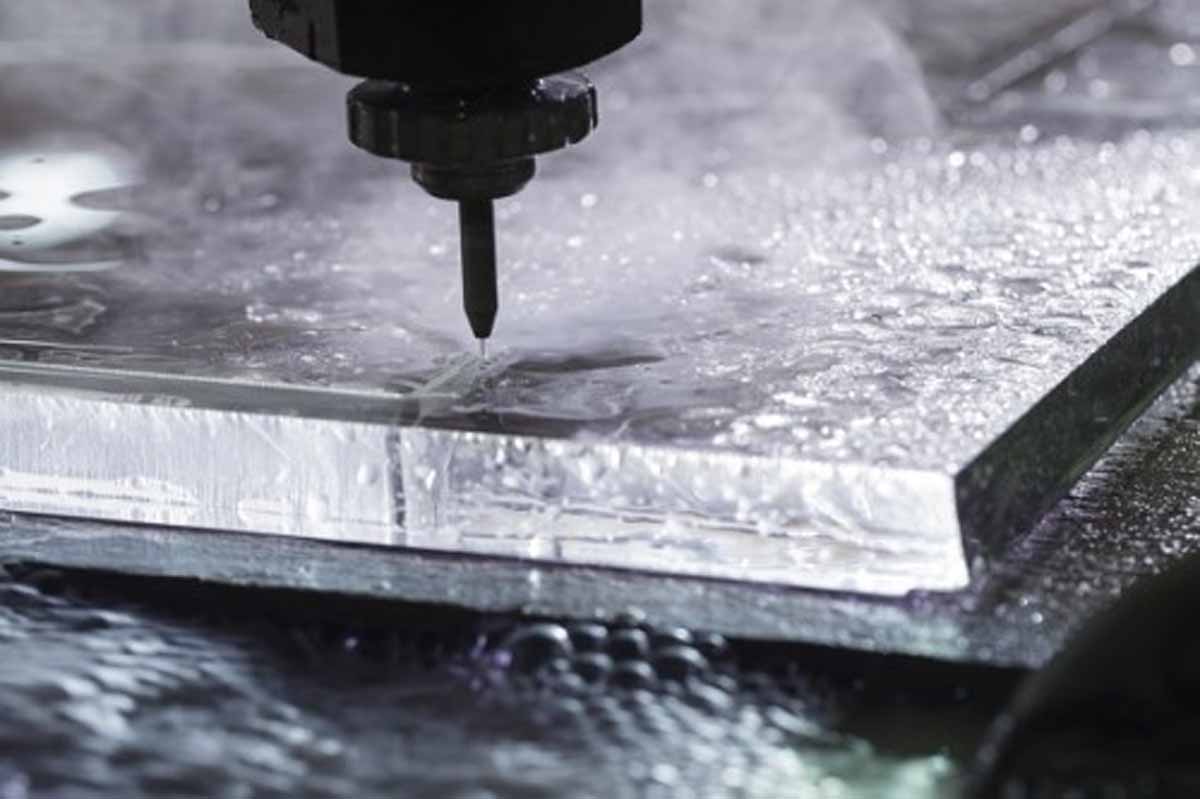

WATER JET SERVICES

With high-pressure water jet technology, we offer precise and burr-free cutting services on a wide range of materials such as metal, glass, ceramics, stone, and composites. The no-heat cutting process ensures that the material structure remains unchanged and the edge quality is top-notch.

- Maximum cutting thickness: 200 mm

- Burr-free and no-heat cutting

- Precise tolerances and smooth edge quality

- Wide material compatibility

- Automatic CAD/CAM-supported programming

- Machine and equipment parts

- Automotive, aerospace, and defense industry

- Glass, ceramics, and stone processing

- Prototypes and special production

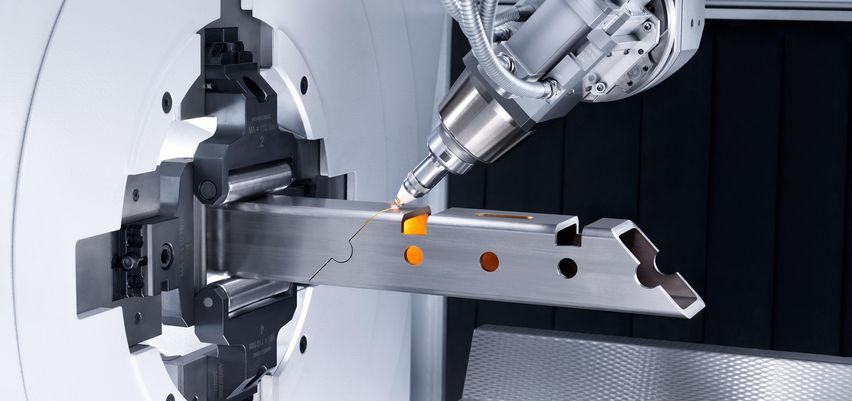

TUBE LASER SERVICES

With high-precision laser cutting on tube and profile materials, complex geometries, holes, and special shapes are produced quickly and accurately. Efficient and repeatable results are achieved with automatic loading and measurement systems.

- Maximum tube diameter: 300 mm

- Maximum tube length: 6000 mm

- Compatible with different cross-sections and profile types

- High precision and fast cutting

- Automatic loading and measurement systems

- Tube and profile constructions

- Machine and equipment manufacturing

- Furniture and decoration products

- Automotive and industrial applications

PROTOTYPE MANUFACTURING SERVICES

We quickly turn your ideas into reality with fast and precise prototype manufacturing. Our modern production technologies offer functional and visual prototypes.

- 3D printing, CNC machining, and casting techniques

- Short lead times

- Functional and visual prototype options

- Various material and surface options

- CAD/CAM-supported production

- Product development and R&D

- Design verification

- Function and assembly testing

- Presentation and customer approval processes

SERIAL PRODUCTION SERVICES

For your high-quantity orders, we offer automation-supported, efficient, and high-quality serial production solutions. We ensure on-time and reliable delivery with process tracking and quality control.

- Automated production lines

- High repeatability and quality

- Various material and part types

- Integrated quality control systems

- Flexible production planning

- Automotive and sub-industry

- Machine and equipment manufacturing

- Electronics and white goods

- Industrial and consumer products

MATERIAL ANALYSES AND CERTIFICATES

Our material analysis and certification services ensure that the produced parts fully comply with quality and safety standards. All our materials are carefully tested and certified to meet industry requirements. Our certificates guarantee the accuracy of material quality and the reliability of our production processes.

- Material certificates (3.2): Third-party certified according to EN 10204 3.2 standard

- Hardness measurement: Rockwell, Brinell, Vickers

- Crack detection: Penetrant testing (PT), magnetic particle testing (MT)

- Chemical composition analysis

- Salt spray test (corrosion resistance)

- Stress and deformation tests

- Automotive

- Aerospace

- Machine engineering

- Power generation

- Construction

- All sectors requiring quality and safety

MATERIAL SUPPLY AND MANAGEMENT

We professionally manage all processes of supply, storage, and management of all materials required for your projects. We ensure the continuity of your production with a reliable supply chain and traceability.

- Wide supplier network and fast procurement

- Material traceability and lot management

- Stock optimization and reporting

- Use of quality-certified and accredited materials

- Project-based material management

- Production and assembly projects

- Raw material and semi-finished product supply

- Stock and warehouse management

- Sectors requiring traceability

TECHNICAL SUPPORT SERVICES

We provide fast and effective support with our expert team for all technical questions and needs you may encounter in your production and project processes. We are here to help you with process improvement and efficiency-enhancing suggestions.

- Project and production consultancy

- Process development and optimization

- Technical training and application support

- Fast problem-solving and on-site support

- Remote technical support option

- Production and assembly processes

- Machine and equipment installation

- Project initiation and commissioning

- Process improvement and efficiency enhancement